Designing a CM5 Carrier Board - A Practical Guide for Makers and Engineers

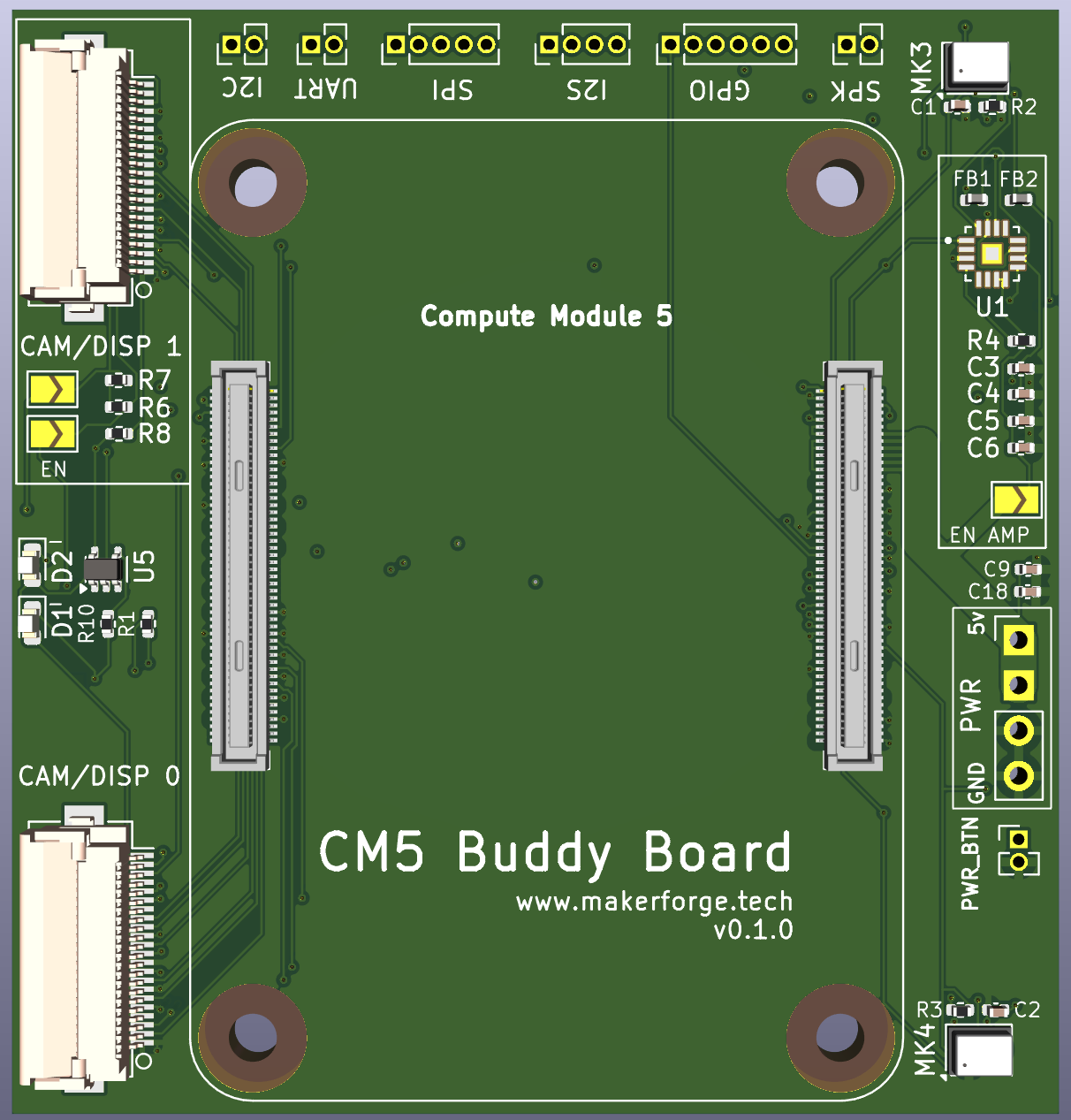

Creating a custom carrier board for the Raspberry Pi Compute Module 5 (CM5) can seem daunting—but with the right tools and best practices, it becomes a highly rewarding venture. Whether you’re building a robot, a smart display, or an embedded controller, a well-designed carrier board ensures stability, reliability, and full access to CM5’s features.

In this post, we’ll walk through both high-level considerations and practical tips for building your own CM5 carrier board—based on real-world experience and community knowledge.

🔧 Essential Resources to Get Started

Before diving into schematics or layouts, gather these helpful files and templates:

✅ Reference Files

Raspberry Pi Official CM5 IO Board KiCad Files

Download from Raspberry Pi

This gives you a solid reference for pinouts, layout, and component usage.Shawn Hymel’s CM4/CM5 Carrier Board Template

GitHub Repo

Move thehardwarefolder into your KiCad base folder (usually in your Documents) for easy access.

🧠 Schematic Tips & Best Practices

Use Hierarchical Sheets

KiCad lets you split designs into multiple sub-sheets for clarity and modularity. Use labels (especially global labels) to connect signals between sheets reliably.- Library Management

- When adding custom components (e.g., regulators, connectors), download both the symbol (

.lib) and footprint (.pretty) from the manufacturer or Digi-Key. - Add these libraries via Project > Manage Symbol Libraries in KiCad.

- Maintain naming consistency for smooth integration.

- When adding custom components (e.g., regulators, connectors), download both the symbol (

- Component Properties Matter

Update each part’s metadata (Manufacturer, MPN, Digi-Key/Mouser Part Number). These fields will be used when generating the Bill of Materials (BOM).

Tip: “Cut tape” is great for sourcing single units.

⚡ Electrical & Mechanical Design Considerations

🪛 General Hardware

- Power Supply: Provide 5.1V @ 5A via a VIN pin.

- Add a Power LED: Simple, but valuable for diagnostics.

- Screw Mounts: Include at least four mounting holes for mechanical stability.

🔄 eMMC Boot Management

To flash the CM5 when using onboard eMMC:

- Add a solder jumper between the

nBOOTpin and GND to disable eMMC boot. - This enables USB booting via the USB-C port—essential for headless devices.

🧩 Interfaces to Expose

| Interface | Pins | Notes |

|---|---|---|

| I2C | GPIO 2 (SDA), GPIO 3 (SCL) | Use pull-ups if needed |

| I2S | GPIO 18, 19, 20, 21 | Audio in/out support |

| SPI | GPIO 8, 10, 11, 25, 27 | Displays, sensors, Neopixels |

| UART | GPIO 14 (TX), GPIO 15 (RX) | Connect GND to complete circuit |

| USB | USB-C (programming), USB-A (peripherals) | One USB-A port is usually enough |

| Camera/Display | CSI, DSI ports | Make both accessible |

| GPIO | 40-pin header | For compatibility with Pi HATs |

📏 Layout & Signal Integrity

🧮 Net Class & Impedance

- Update Design Rules: Set default track width and clearance to 0.2mm to match the fine-pitch CM5 connector.

- USB Data Lines: These require differential impedance.

- Follow a coupled microstrip line design.

- Use tools or calculators (like Saturn PCB) to determine trace width/gap.

- Create a dedicated Net Class in KiCad for USB differential pairs (D+ and D−).

👉 For more detail, check: Octavo Systems USB Design Tutorial

Shawn Hymel’s CM4 Design Video (Part 1)

📌 Additional Layout Tips

- Fiducials: Place two 1mm fiducials in opposite corners to help pick-and-place machines align the board.

- Connector: Use a Hirose connector (the same one used in the CM5 IO board) for CM5 compatibility.

👉 Follow the Discussion

Take a look at this post on the MakerForge GitHub for a community-driven discussion on CM5 carrier board design. It’s a great place to ask questions, share your designs, and learn from others.

🧪 Final Thoughts

Designing a CM5 carrier board is a blend of electrical engineering, mechanical design, and a bit of artistic layout finesse. By using community resources, following standard practices, and taking time to carefully manage signal integrity and component sourcing, you can create a robust platform tailored to your application.

Whether you’re building a robotic platform like the Modular Biped or a custom embedded system, this guide should help you make smart, future-proof design choices.

Happy prototyping!